Discuss the method of cleaning the surface of stainless steel castings

The surface cleaning of stainless steel castings is divided into two categories: dry method and wet method. The dry cleaning method is mainly shot blasting. The wet washing method is mainly based on hydraulic sand cleaning and water washing. The dry cleaning method is shot blasting. The main friction treatment method is to clean the surface of stainless steel castings. To put it simply, shot blasting is powered by compressed air to spray projectiles onto the surface of stainless steel castings at a certain speed to remove sand and oxide scale on the surface, but this method of friction cleaning is used. Because of low efficiency, uneven cleaning, and poor results, it has been eliminated by many foundries and almost eliminated.

The wet cleaning method is mainly based on the principle of the electro-hydraulic hammering effect. The high-voltage pulse generator discharges through special electrodes placed in the water, generating huge hydraulic shocks. Because the surface adhesion of stainless steel castings is different from the elastic modulus and vibration frequency of the casting itself, the purpose of sand removal is achieved. For stainless steel castings with complex shapes, such as deep holes, blind holes, inner cavities, etc., it has a relatively effective cleaning effect. It is currently the most widely used surface cleaning method for a series of castings including stainless steel castings.

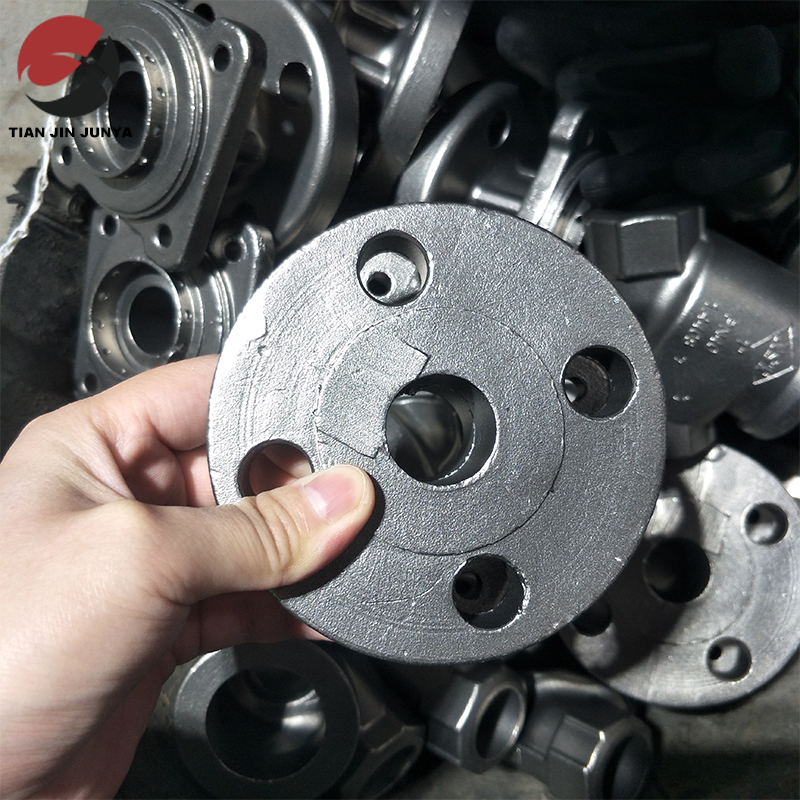

The above are two commonly used cleaning methods for the surface of stainless steel castings. It should be reminded that these two cleaning methods are not only suitable for stainless steel castings. Most metal castings require surface cleaning during the post-processing process. Cleaning is an indispensable process in metal casting products. For the cleaning of the surface of castings, the main function is to remove a series of impurities such as sand and iron oxide on the surface of metal castings, so that the surface of stainless steel castings becomes stainless steel. The gloss conforms to the product’s implementation standards, so the surface cleanliness of stainless steel castings is very important. The correct method must be followed when cleaning the surface of stainless steel castings. To ensure the quality of stainless steel casting products.

www.junyacasting.com

Post time: Dec-17-2021